Our Precision Cutting Services

From design and application of fasteners, to inventory management solutions; we help increase efficiencies and reliabilities for our customers.

Profile Cutting

Blades Australia use Hypertherm and Kinetic as its plasma cutting partners with true hole technology. We do high quality cutting on thickness between 2mm and 32mm.

Heat Treatment

Blades Australia has expertise in flame hardening and quenching in oil or water and Tempering to specification. We also have capabilities in stress relieving and moulding of spring steel up to 20mms in thickness.

Ceramic Cutting

Our equipment enables us to cut ceramic blocks up to 75 mm in thickness.

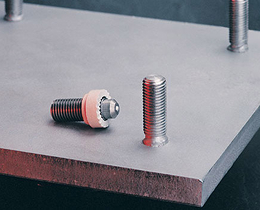

Stud Welding

We have a Soyer stud welder, with the capability to weld Shear / Threaded studs from 8 mm to 25 mm diameter as required. Please enquire for our range of wear plates/angles and Cast in plates. Stocks may be limited and lead times apply.

CNC Machining

Blades Australia has two Fenuc controlled CNC machines. We provide precision drilling and machining.

Case Hardening

Blades Australia case harden mild steel from 0.1mm to 1.2mm in depth. We also have specific case hardening applications for tool steel. Pot size – 600mm x 900mm in depth. Temperatures up to 1120 degrees Celsius.

Slash Grinding

Blades Australia has strong surface grinding capabilities with four large format slash grinders with up to 80hp capacity. Our largest magnetic bed size is 2100 x 510 mm.

Stock Material

Our stock holding: 250 grade 3 – 32 mm., 350 grade 10 – 32 mm., Hardox 450 grade 6 – 25 mm., Checker plate 3 – 10 mm. This enables us to supply on the day of order if required.

Profile Cutting

Blades Australia use Hypertherm and Kinetic as its plasma cutting partners with true hole technology. We do high quality cutting on thickness between

2mm and 32mm.

Heat Treatment

Blades Australia has expertise in flame hardening and quenching in oil or water and Tempering to specification. We also have capabilities in stress relieving and moulding of spring steel up to 20mms in thickness.

Ceramic Cutting

Our equipment enables us to cut ceramic blocks up to 75 mm in thickness.

Profile Cutting

We have a Soyer stud welder, able to weld studs from 8 mm to 25 mm diameter as required.

CNC Machining

Blades Australia has two Fenuc controlled CNC machines. We provide precision drilling and

machining.

Case Hardening

Blades Australia case harden mild steel from 0.1mm to 1.2mm in depth. We also have specific case hardening applications for tool steel. Pot size – 600mm x 900mm in depth. Temperatures up to 1120 degrees Celsius.

Slash Grinding

Blades Australia has strong surface grinding capabilities with four large format slash grinders with up to 80hp capacity. Our largest magnetic bed size is 2100 x 510 mm.

Metal in Stock

Our stock holding: 250 grade 3 – 32 mm., 350 grade 10 – 32 mm., Hardox 450 grade 6 – 25 mm., Checker plate 3 – 10 mm. This enables us to supply on the day of order if required.